Vertical Integration: Where Quality Begins

From precision CNC machining to automated assembly, we control every micron within our 100% in-house facility.

Machining

Precision Machining & Material Sourcing

Premium Sourcing

We insist on sourcing Japanese-imported core materials and Taiwan-certified raw materials to guarantee quality from the start.

Japanese-Grade Equipment

Utilizing Japanese mill-turn composite machines paired with Japanese and Swiss tooling, we achieve 100% in-house manufacturing to precisely control every detail.

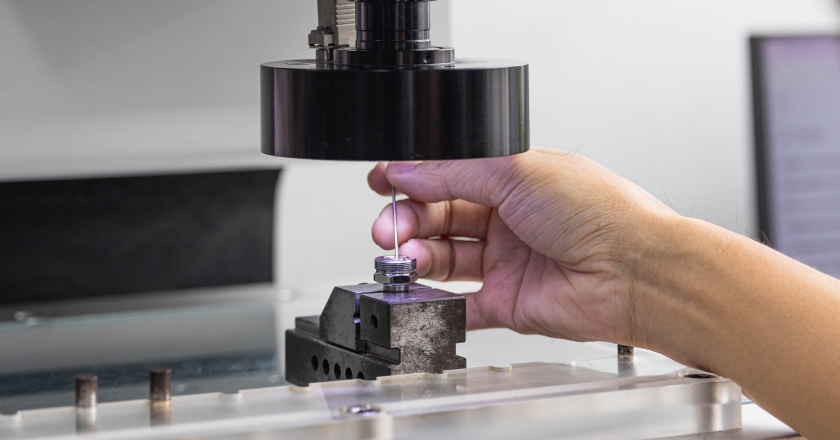

Rigorous QC

Machines are set to auto-inspect every hour. We also utilize 2.5D/3D measuring instruments and surface roughness testers to ensure all tolerances strictly meet engineering blueprints.

Reinforcement

Structural Reinforcement & Surface Treatment

Clean Foundation

Parts undergo deep ultrasonic cleaning to ensure zero oil residue, laying a perfect foundation for subsequent processing.

Green Welding

Introducing eco-friendly welding technology to significantly reduce oil and water consumption (ESG), verified by 100% airtight leak testing to ensure flawless structural integrity.

Automated Polishing

Replacing manual labor with automated polishing equipment not only supports eco-friendly operations but also ensures consistent surface flatness and luster for every unit.

Aesthetics

Aesthetics & Visual Inspection

Craftsmanship Inspection

Professional inspectors examine welding points and polished surfaces under magnifying glasses before and after plating to eliminate over-polishing or defects.

Exquisite Plating

High-quality electroplating imparts superior corrosion resistance while presenting a jewelry-like premium luster.

Assembly

Precision Assembly & Core Inspection

Heart of the Airbrush

The needle and nozzle are the soul of the airbrush. Before entering the assembly line, we perform 100% high-magnification microscopic inspection to ensure zero eccentricity and burrs, the absolute prerequisite for fine atomization.

Craftsman Assembly

Precision assembly is carried out by experienced technicians to ensure the fit tolerance of every part achieves the best tactile feedback—a detail of craftsmanship that machines cannot replace.

TESTING

Rigorous Performance Testing

Ultimate Sealing Test

Finished products must pass strict "water and paint blocking tests." This means when the trigger is released, airflow and fluid must be completely cut off, ensuring zero leakage or dripping and demonstrating perfect airtightness.

Dual Action Verification

Technicians physically test the smoothness of the Dual Action system, ensuring the linear linkage between "down for air" and "back for paint" is precise, allowing users to control line width with total freedom.

Packaging

Eco-Packaging

Green Packaging

Adopting 100% recyclable color box designs to fulfill our plastic reduction commitment, protecting both the product and the planet.

Flexible Supply

Comprehensive inventory management for both parts and finished goods allows for rapid response to global market demands and urgent orders.